Precision Coated PET Films: Enhancing Functionality and Adhesion for Displays

Today’s displays are more advanced than ever before, requiring materials that can keep up with demanding environments and intricate device designs. One essential component in this advancement is the custom coated PET film, which allows manufacturers to tailor optical, mechanical, and adhesive properties to the specific needs of the product.

1. What Makes PET Coating “Custom”?

Custom coated PET films are developed by modifying the surface of polyethylene terephthalate with specialty coatings. These coatings serve different functions depending on the application, including:

- Improving ink or adhesive bonding

- Controlling light reflection and diffusion

- Enhancing resistance to abrasion, UV, or chemicals

This flexibility makes custom PET ideal for high-performance screens, especially in mobile electronics and automotive displays.

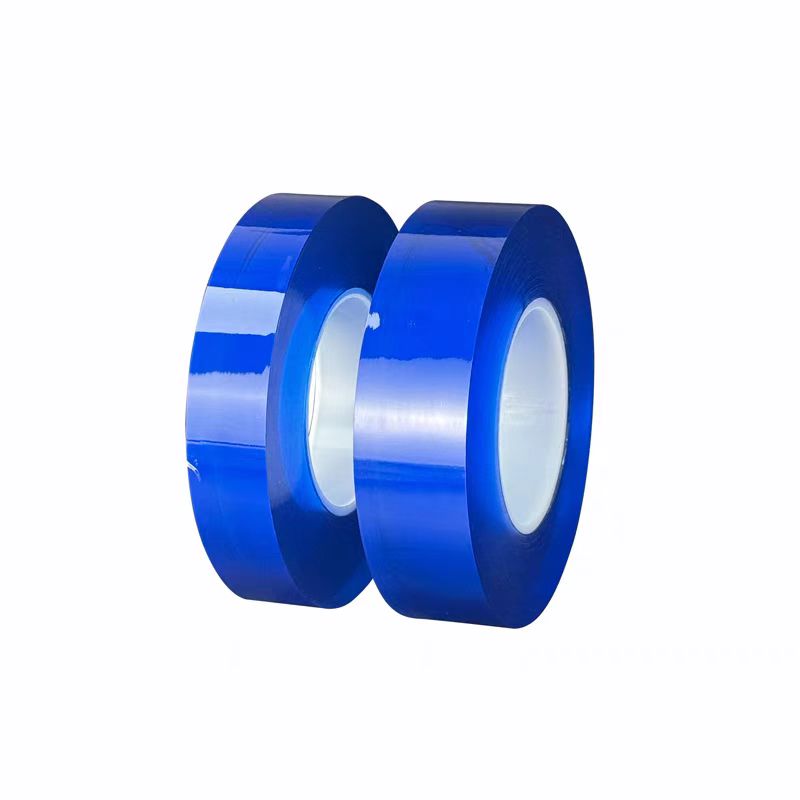

2. Self Adhesive PET Film for Streamlined Assembly

Self adhesive PET film has transformed how manufacturers and consumers apply protective and functional layers to screens. These films come pre-coated with pressure-sensitive adhesives, offering several advantages:

- No additional adhesive required during application

- Consistent bond strength with minimal bubbles

- Repositionable and removable options available

This makes them popular for screen protectors, overlay panels, and repair components.

3. The Role of Functional PET Film Manufacturers

A reputable functional PET film manufacturer provides more than just raw materials. They offer engineering support, material customization, and precision coating technologies. Their services include:

- Prototyping small batches for R&D

- Consistency in large-scale production

- Meeting ISO and display-grade quality standards

Collaborating with the right manufacturer ensures the film performs consistently in real-world conditions.

4. Applications in High-End Display Technologies

Custom coated PET and self adhesive PET film are now used in:

- OLED and LCD screen laminates

- Touch sensor overlays and control panels

- Transparent functional layers in AR/VR optics

These solutions require precise layering and high optical clarity, which only premium PET films can deliver.

5. Future Trends in Coated PET Films

Manufacturers are now exploring innovations such as:

- Anti-microbial surface coatings for healthcare screens

- Low-VOC and eco-friendly adhesive PET film types

- High-transmission films for brighter, battery-efficient displays

Expect a functional PET film manufacturer to play a key role in delivering these future-ready solutions.

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.