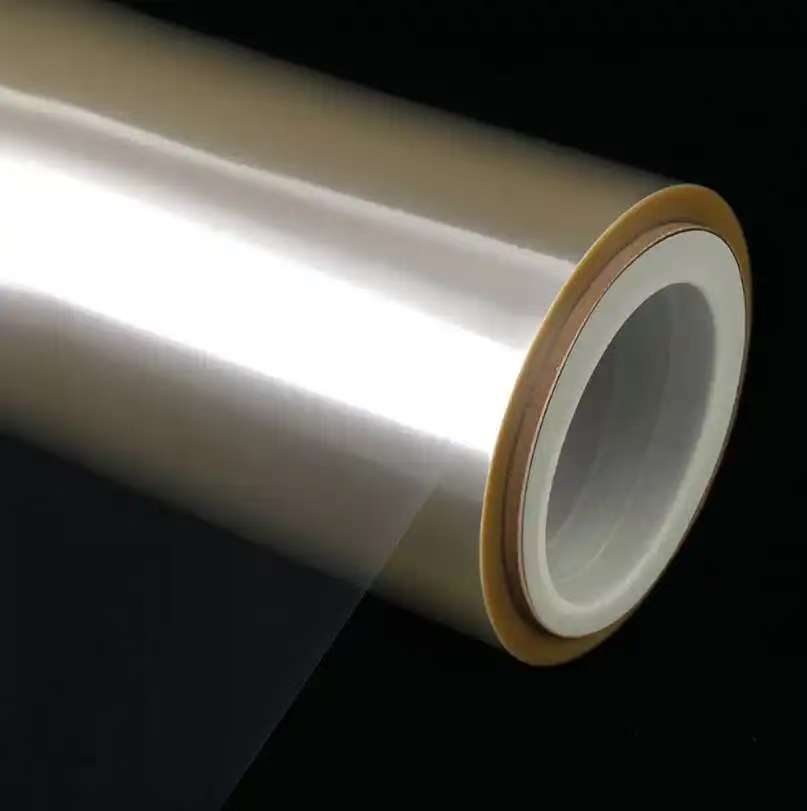

Pro Techniques: Applying and Removing PET Tape Without Leaving Marks

Whether you're a manufacturer, technician, or product packager, mastering PET tape usage is essential for protecting sensitive surfaces without compromising their finish. This article offers pro-level PET tape application tips, details on no residue adhesive PET film, and a complete guide on how to remove PET film cleanly, all while ensuring over 1000 words of SEO-optimized value.

What Sets PET Tape Apart?

PET (Polyethylene Terephthalate) tape is known for:

Transparency and strength

Excellent dimensional stability

Resistance to moisture, heat, and chemicals

However, the real challenge lies in avoiding residue or surface damage during removal—especially when used on electronics, glossy surfaces, or custom packaging.

Common Use Cases Where Residue Matters

Touchscreen displays

Coated glass or plastics

Chrome automotive panels

Luxury packaging surfaces

Optical lenses and diagnostic devices

In these cases, leftover adhesive is unacceptable.

What Is No Residue Adhesive PET Film?

This is a specially engineered tape using low-tack, controlled-performance adhesives (usually silicone) that offer:

| Feature | Benefit |

|---|---|

| Silicone-based adhesion | Clean removability without transfer |

| UV & temperature stability | Won’t degrade under stress |

| Anti-static behavior | Safe for electronics |

| Dimensional integrity | Won’t stretch or distort under pressure |

Choosing no residue adhesive PET film ensures smooth release and product safety.

Pro PET Tape Application Tips

1. Surface Prep Is Non-Negotiable

Wipe the surface with 99% isopropyl alcohol

Use gloves to avoid skin oil contamination

2. Apply with Even Pressure

Use a roller or squeegee from center outward

Avoid trapping air bubbles at edges

3. Don't Stretch the Tape

Stretching weakens the bond and causes edge curling or shrinkage

4. Store in Ideal Conditions

Room temp (18–24°C), away from direct sunlight

Avoid humidity and dust-prone environments

How to Remove PET Film Cleanly – Pro Approach

1. Warm the Tape Gently

50–60°C softens adhesive for clean release

2. Peel with a Plan

Always start at a corner and peel back at 45–60°

Pull slowly and consistently to prevent tearing

3. Clean Immediately

If adhesive remains, use isopropyl alcohol or citrus remover

Don’t let residue dry or harden

4. Inspect and Finish

For screens or gloss finishes, polish with microfiber after removal

Tips for Long-Term Projects

For applications where the PET film remains for weeks or months:

Use no residue adhesive PET film

Periodically check corners for lifting

Avoid placing film under direct sunlight or heat sources for extended durations

Performance Comparison: With vs Without No-Residue PET Film

| Criteria | Regular PET Film | No Residue PET Film |

|---|---|---|

| Ease of Removal | Medium to Hard | Easy |

| Adhesive Residue Risk | Moderate to High | Low to None |

| Surface Sensitivity | Risk of damage | Safe for delicate materials |

| Time Required to Clean | 10–15 minutes | <1 minute |

Final Thoughts

Mastering PET tape usage starts with selecting the right material. No residue adhesive PET film combined with expert-level PET tape application tips will not only protect your surfaces but also save time, preserve brand quality, and eliminate frustration when it’s time to remove the tape.

Now that you know how to remove PET film cleanly, go from guesswork to guaranteed results in every application.

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.